Single Column Vertical Lathe CK5116 CNC Heavy Duty Vertical Lathe Machine

Product Description

Single Column Vertical Lathe CK5116 CNC Heavy Duty Vertical lathe machine

Vertical Lathe Machine Cnc Vertical Lathe Manual Vertical lathe cnc column Vertical Lathe vertical Lathe cnc turning vertical lathe turning vertical lathe Vertical Lathe Machine price

Description:This series machine can carry out operations on the materials of ferrous metal , nonferrous metal and part non-metal , int. and ext. Cylinder turning, taping, curving, threading in metric or inch and kinds of complex swiveling surface can be carried out on the machine.

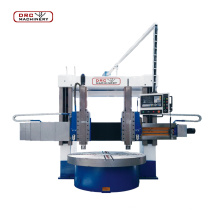

Features:The Single-column model CK5116 is a super rigid machine with big machining capacities, stable and rigid structure and high machining efficiency.

The machine is equipped with one vertical tool head and AC inverter motor is used to achieve speed change.

Gears are made of 40 Cr steel and precision ground for high precision and low machine noise.

The machines are designed and built to meet modern machining requirements of high speed cutting tools and carbide cutters on workpieces of ferrous, non-ferrous, composite and other materials.

Lathe Machine Main Structure:

1. Machine Tool : The main parts of the machine tool ( lathebed, base, workbench, beam, vertical slide rest, side tool box, feed box, main drive gear box) are made of high-strength cast iron, casted by resin sand technology

2. Main drive: The rotation of workbench is drove by main electrical machine, gear slowing down and electromagnet speed changing system to implement speed regulation

3. Vertical slide and feed mechanism of the vertical slide: The material quality of RAM is HT250. Its mechanical character is very good.

4. Workbench base structure: Workbench adopts long spindle structure. Radial direction adopts high-precision double row cylindrical roller bearings centering.

5. Beam: Beam clamps and loosens by a drift. The clamp is implemented by hydraulic pressure.

6. The hydraulic pressure system: The main control originals of the hydraulic pressure system come from the products of famous manufactures at home and abroad.

7. Lubrication of machine tool: The machine tool will offer oil automatically to lubricate the beam and the movement parts concentratedly at specified time.

Machine specifications:

| Name | Unit | CK5116 |

| Max. turning diameter | mm | 1600 |

| Max. height of workpiece | mm | 1200 |

| Max. height of workpiece | t | 3.2 |

| Workbench diameter | mm | 1400 |

| Workbench speed series | step | 16 step/two gears no step |

| Workbench speed range | r/min | 15~160 |

| Max. workbench torque | KN.m | 10 |

| Main motor power | KW | 30 |

| Max. cutting force of knife rest | KN | 16 |

| RAM travel of vertical slide | mm | 800 |

| Fast moving speed of knife rest(X axis Z axis) | mm/min | 2000 |

| Level travel of vertical slide | mm | -20~915 |

| Feeding series of knife rest(X axis Z axis) | step | no step |

| Feeding range of knife rest(X axis Z axis) | mm/min | 0.1~2000 |

| Section height of knife carrier | mm | 32x32 |

| Feeding alternating servomotor torque | N·m | 11/16 |

| Beam travel | mm | 700 |

| Beam movement speed | mm/min | 440 |

| Beam lifting motor power | KW | 2.2 |

| Positional precision |

| 0.03/1000mm |

C51/CK51 series machine is Single Column Vertical Lathe ,it has a railhead and a sidehead ,Vertical lathe machine is suitable to process ferrous metal, nonferrous metals and partial non-metallic material, and could achieve the processing of turning of the End Face , inside and outside cylindrical surface, inside and outside circular conical surface and drilling, expanding, reaming of the hole. The vertical lathe machine cutting action is controlled by the PLC, and feeding axis is driven by the AC asynchronous servo motor, with touch screen display and hand-held pulsed. Main transmission is driven by the spindle AC servo motor, hydraulic gear change and two gears stepless speed regulation. Tool rest adopts the T-type ram manual 5-tool position tool table structure with good rigidity and convenient tool change. Worktable is manual 4-jaw single movement chuck.It can perform finely and roughly turning cylinder and inner hole,inner and outer taper, grooving ,drilling ,tapping and reaming.

DRC has strong technical force, the advanced production equipment, and the perfect administration system. Our productions have good quality, advanced technology.These single & double column lathe and NC vertical lathe have gained perfect praise by consumers since put into market.

Based on excellent processing equipments, strong technical force, perfect inspection way, and inpectable management system. Baili Machine has passed National ISO9001:2008 Quality Management System Certification.

1. Tool Holder :Tool holder’s screws adopt special steel, hardening treatment, guarantee wear well. Pentagon tool holder can be equipped by any tools, such as drilling, boring and turning and so on. Exact position, fast clamping, easy operation.

2.Ram:Ram adopts high strength nodular cast irono, with high compression strength and good abrasive resistance, ensure the stiffness whtile the machine heavy cutting. According to the requirement of workpiece, square ram and pentagon tool can be optional.

3.Spindle bearing:Spindle bearing adopts the inland famous brand, improve the accuracy of the machine, long use period. The construction of the worktable is designed as the standard technological requirements, which can make the strength of the worktable improve greatly and it is not easy to deform and crack, good stability when using for a long time.

4.Worktable:The base of the worktable is annealing treatment, after turning, the guideway and the joint surface of worktable is hand scraping, the closed by oil film to ensure stable run.

5.Worm gear:The worm gear in the elevating box and the feed box adopts the latest allumen to ensure the parts abrade lightly and increase of service life when using.

Cnc Single Column Vertical Lathe

• This series machine is suitable for internal and external turning, internal and external tapering, facing, slotting, thread, contour surface turning ( CNC Machine ) etc.

•This series machine is Single Column Vertical lathe, it has a railhead and a side head, it is suitable of the ferrous, non ferrous metal and some kinds of non-metal materials with hard alloy, high capability and high speed steel tools.

Controller:

Fanuc, GSK, SIEMENS, KND, Mitsubishi

1. What is your minimum order quantity and warranty?

MOQ is one set, and warranty is one year.

2.What CNC system do you use?

FANUC, SIEMENS, MISTSUBISHI, GSK etc. It depends on your choice.

3.When is the delivery time?

We will delivery it within 90 days after received your payments

4. How to handle the warranty period?

During the warranty period, because of product quality problems, the company is responsible for free maintenance, if need to change parts, we be responsible for free replacement.

If the machine problem is not belonging to our machine quality problems, when the buyer needs us send engineers to give repairing service, we charge the appropriate cost.

5.Can your company send the technical personnel to our company and direct our workers for free?

When the machine arrive the buyer’s installation site, we timely send mechanical and electrical engineers to install according to the buyer's schedule, the buyer undertakes board and lodging of personnel abroad in the process of installation, and also USD100.00 per day per person. The seller will cooperate with the buyer to deal with visa and installation preparation before going abroad.

6.What's the trade assurance?

When you look at our alibaba website, you will see the trade security, its purpose is to let every buyer confidence, it can protect your payment, ensure that the suppliers fulfill their commitment to the date of shipment and the quality of the products (as you stated in the purchase order).

If the supplier finds breach of these contractual obligations, alibaba will indemnify you for 100% of your trade guarantee.

Therefore, I believe that through trade guarantees, you will have greater confidence to cooperate with us.

Our company has US $128000' trade assurance limit, it can guarantee your interests.

7.Do your products support trade assurance?

Yes, our products are all supported.

Send your Inquiry Details in the Below , Click "Send" Now !

Product Categories : Other Lathe Machine > Vertical Lathe

Premium Related Products