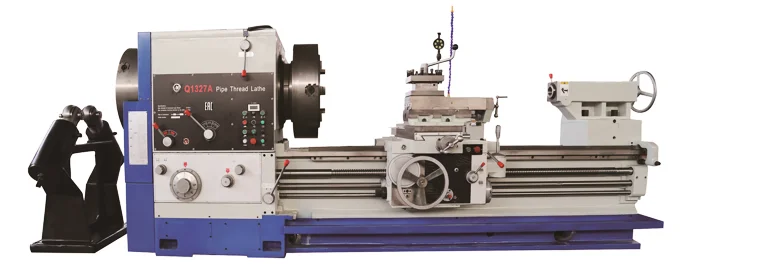

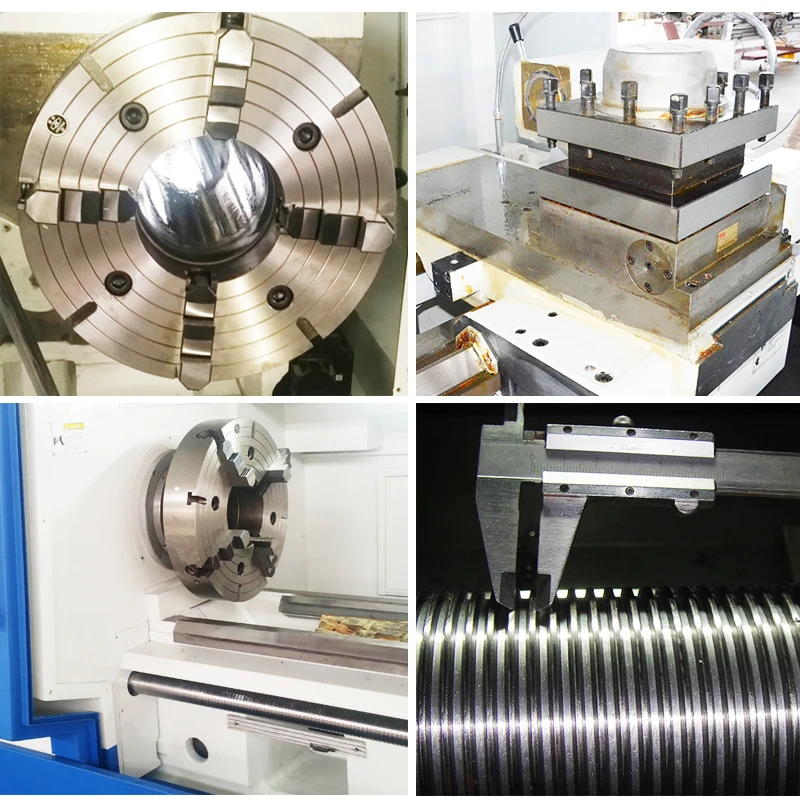

Normal Manual 3 Jaw Chuck Machining Metal Horizontal Lathe Machine

Product Description

Normal Manual 3 Jaw Chuck Machining Metal Horizontal Lathe Machine

Normal Manual 3 Jaw Chuck Machining Metal Horizontal Lathe Machine

Q13 series pipe thread Lathe is specially developed by our company for the processing of AP pipe threads in the oilfield industry.The Machine Tool has a large spindle through-hole and a double chuck clamping structure on the front and back.It is suitable for all kinds of long pipe cylindrical threads, tapered threads and Turning of special threads.At the same time, it also has all the functions of ordinary CNC lathes. It can replace ordinary CNC lathes to process complex shaped shafts, sleeves, disks and other parts, such as turning inner and outer cylindrical surfaces, conical surfaces, arc surfaces, end faces , Grooving, chamfering, threading, etc., strong process adaptability, high processing efficiency, uniform product. This machine tool has a novel appearance, simple operation, mature structure and stable performance, and is widely used in petroleum, natural gas, chemical, hydropower, and geological exploration departments.

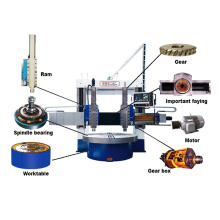

Structural features of pipe thread lathe:

1. The bed is made of high standard cast iron (HT300) secondary molding and casting. After secondary aging treatment, it has strong stability, good rigidity and strong seismic resistance.

2. The guide rail surface is subjected to high-frequency quenching (Rockwell hardness can reach HRC55 or higher). The imported guide rail grinder is used for precision grinding to ensure long life, high accuracy and good retention of the guide rail surface.

3.3 The headstock box of the 3 spindle is completed by one-time molding of the imported horizontal boring and milling Machining Center. The spindle has high concentricity, strong structural rigidity, and can adapt to heavy cutting. Stable, both recutting and finishing.

4. Automatic forced circulation lubrication makes the transmission system run flexibly and can effectively cool down. Each sliding rail pair is coated with TSF soft belt, which greatly reduces the friction coefficient and improves the service life of the rail.

5. Equipped with a four-station electric tool post as standard, quick and easy tool change.

What Is The Specifications of Pipe threading lathe?

| Main Techinical specifications | Unit | Q1323A | Q1327A | Q1343A |

| Swing over bed | mm

| 630 | 800 | 100 |

| Swing over carriage | 340 | 540 | 610 | |

| Tube outside diameter | 50-220 | 100-275 | 270-430 | |

| Max length of workpiece | mm | 1500 3000 5000 | ||

| Max length of turning | 1350 2850 4850 | |||

| Span of guideway | 550 | 550 | 755 | |

| Max load of Lathe bed | KG | 3000 | 5000 | |

| Quenching hardness | ≤HRC55 | |||

| Spindle bore(dia) | mm | 225 | 280 | 440 |

| Range of spindle speed | r/min | 20-450 | 10-300 | 10-230 |

| Power of main motor | 11 | 15 | 22 | |

| Motor frequency converter | ||||

| Size of chuck | 500/3 jaw | 800/4 jaw | 1000/3 jaw | |

| Transverse feed range | r/min | 0.05~0.75/32 | ||

| Longitudinal feed range | 0.1-1.5/32 | |||

| Screw pitch of leadscrew | mm | 12 | ||

| No and range of inch thread | 2-28/22 | |||

| Rapid traverse speed | mm/min | 4000 | ||

| Section of tool shank | mm | 32 | 40 | |

| Dia /Travel of tailstock quil | 100/250 | 140/300 | ||

| Taper hole of tailstock quill | Morse 5 | Morse 6 | ||

| I Max taper machining length | 700 | |||

| Length ( L) | 3700/5200/7200 | 4400(1.5m) | 5800(1.5m) | |

| Width(W/H) | 1900/1700 | 2080/1950 | 2250/2250 | |

| Machine weight (1500mm) | KG | 5200 | 7500 | 13000 |

Who Is DRC?

DRC is a group company ,which is professional in products and sales of advanced CNC Machine tools . Acting full operation of the six machine tool production company's overseas sales.

DRC is located in Dalian, which is one of the largest seaport cities of China.Our products exported to Russia, Dubai, Hungary, Italy, Argentina, the Philippines, India more than 50 countries.

DRC has six factories in China, which covers many kinds of mechanical equipment.

Product Range:

Lathe

CNC Lathe

Conventional Lathe

Vertical lathe

Machining Center

Wheel Repair Lathe

Planer & Slotting Machines

Boring and milling machine

Laser Cutting Machine

Special Machine for Pipe Threading Lathe, Valve Milling, End Facing Machine and so on

What Is The Historical Order Of DRC?

Below are some orders , click the photo to get more information.

1. What is your minimum order quantity and warranty?

MOQ is one set, and warranty is one year.

2.What CNC system do you use?

FANUC, SIEMENS, MISTSUBISHI, GSK etc. It depends on your choice.

3.When is the delivery time?

We will delivery it within 90 days after received your payments

4. How to handle the warranty period?

During the warranty period, because of product quality problems, the company is responsible for free maintenance, if need to change parts, we be responsible for free replacement.

If the machine problem is not belonging to our machine quality problems, when the buyer needs us send engineers to give repairing service, we charge the appropriate cost.

5.Can your company send the technical personnel to our company and direct our workers for free?

When the machine arrive the buyer’s installation site, we timely send mechanical and electrical engineers to install according to the buyer's schedule, the buyer undertakes board and lodging of personnel abroad in the process of installation, and also USD100.00 per day per person. The seller will cooperate with the buyer to deal with visa and installation preparation before going abroad.

6.What's the trade assurance?

When you look at our alibaba website, you will see the trade security, its purpose is to let every buyer confidence, it can protect your payment, ensure that the suppliers fulfill their commitment to the date of shipment and the quality of the products (as you stated in the purchase order).

If the supplier finds breach of these contractual obligations, alibaba will indemnify you for 100% of your trade guarantee.

Therefore, I believe that through trade guarantees, you will have greater confidence to cooperate with us.

Our company has US $128000' trade assurance limit, it can guarantee your interests.

7.Do your products support trade assurance?

Yes, our products are all supported.

Send your Inquiry Details in the Below , Click "Send" Now !

Product Categories : Other Lathe Machine > Specialized Machine for Pipeline

Premium Related Products