New Germany Heavy Cut CNC Lathe Machine Spindle speed 5000r/min HT6MY Metal Lathe Turning And Milling Machine

Product Description

Product Description

New Germany Heavy Cut CNC lathe machine Spindle speed 5000r/min HT6MY Metal Lathe Turning And Milling Machine

CNC Lathe is a four-axis linkage, fully closed-loop CNC Machine Tool. The machine machine-electric-hydraulic integrated layout adopts a fully enclosed protective cover, the door opens to the left, a and the operating table is located on the right end of the fixed protective cover, and the ergonomic swing design makes the operation more convenient. Each servo feed shaft adopts high-speed silent ball screw, elastic coupling is directly connected, fast moving speed, low noise, high positioning accuracy and repeated positioning accuracy; the servo motor is equipped with an absolute value encoder, no cumulative error, no memory, No need to find a reference point, the position information will not be lost after the power is cut off. The Machine Tool has strong functions, high precision, reasonable layout, beautiful appearance, easy operation and convenient maintenance.

Super Rigidity: The machine structure is integrated intoa strong base, lower barycenter, 45° saddle design to achieve better vibration damping and reduce deformation providing headstock turret with a very stable base. 45° slant bed structure, more convenient for bar loading unloading smoother for chip removal. Customized CNC Package: HT series have optional FANUC Oi-TF+ control with Manual Guide i packageSiemens 828D control with Shopturn package, 10. 4 display, extra interfaces etc. ready for customers. Abundant Options: Servo turret. servo-driven turret upgrade spindle power, upgrade spindle torque, upgrade bore of cylinder chuck, drawer type coolant tank, tool probe, oil-mist seperator etc. options ready for customers. High Efficiency Line Operation(optional): Thanks to the advanced truss transmission device, it is possible to combine multiple machines with a single task, greatly reducing the transmission time between each process and increasing efficiency.

New Heavy Cut Cnc Lathe Machine Metal Lathe Turning And Milling machine

1. Distributor HT5M/ Industry:Fludics/ Material: 16MnCr5/ Size: 32x150mm/ Complete machining with driven tools 2. Flange/ HT6M/ Industry: Mechinery/ Material: Ck45/ Size: 200x40mm/ Drilling holes with driven tools 3. Shaft HT6M/ Industry: Mechinery/ Material: 42CrMo4/ Size: 40x100mm/ Profile groove with repeat function in the groove cycle 4. Connector/ HT5M/ Industry: Machinery/ Material: Ck45/ Size: 80x20mm/ Complete machining with driven tools 5. Sealing Shaft/ HT6/ Industry: Hydraulics/ Material: 42CrMo4/ Size: 60x320mm/ Turning of complex internal and external profiles 6. Reduce sleeve/ HT5/ Industry: Hydraulics/ Material: Ck45/ Size: 70x80mm/ Chatter-free surfaces using the' Alternating Speed technology cycle Highlights: 1. Compact design with HT300 high tension Meehanite cast-iron machine bed. 2. Perfect accessibility and optimal working depth. 3. The ideal machine for training, with minimal space ocupy and suitable working depth to the spindle. 4. Increased productivity with up to 16 driven tools(optional). 5. Most updated CNC control technoligies: FANUC OiTF+ with Manual Guide i (as standard package) or SIEMENS 828D with Shopturn function (as standard package), and plenty of customized interface prepared.

Minimal Space Ocupation. User-Friendly Operation Panel . Maximum Working Space. Abundant Options.

Twin Turret:

Quick and precise production thanks to the rapid servo-driven turret for maximum process reliability. One time clamping finish turning, milling, drilling tapping operations .

HT2M: 12positions VDI30 /8 positions BMT45 .

HT3M: 12positions VDl30/12positions BMT55.

HT5M: 12positions BMT55/12positions VD140 .

HT5M: 12positions BMT55/12positions VD140 .

HT6M/Y: 12positions BMT55/12positions VD140/16 positions BMT45 Driven tools for machining complex workpieces 12 tool stations, 4,000 rpm, 362Nm, 3 kW.

Ultimate Cutting Capability:

Headstock with heat sink design is integrated casting.Rigid tapping function as standard to realize high-speed precise tapping without floating tapping collets. Easy to program better tapping accuracy, offers maximum tapping productivity With high performance V-belt driving spindle, make maintenance easier, also reduce the impact of the spindle accuracy from the heat on spindle motor conducting. By adjusting pulley reduction ratio, to synchronize the spindle the motor maximum rpm, thereby reducing the minimum rpm of the maximum power output increasing torque, which maximize spindle motor's potential achieve maximum turning capability.

Headstock with heat sink design is integrated casting.Rigid tapping function as standard to realize high-speed precise tapping without floating tapping collets. Easy to program better tapping accuracy, offers maximum tapping productivity With high performance V-belt driving spindle, make maintenance easier, also reduce the impact of the spindle accuracy from the heat on spindle motor conducting. By adjusting pulley reduction ratio, to synchronize the spindle the motor maximum rpm, thereby reducing the minimum rpm of the maximum power output increasing torque, which maximize spindle motor's potential achieve maximum turning capability.

New Heavy Cut CNC Lathe Machine Metal Lathe Turning And Milling Machine

Y Axis:

CT5: 12positions BMT55 turret, Y axis travel t35

CT6: 12positionsBMT55turret, Y axis travel+50 16positions BMT45turret, Y axis travel+45 Main Drive Spindle Motor: Main drive system using FANUC/SIEMENS high performance servo spindle motor, through V-belt transimission power, to the patent design of high rigidity spindle structure with 3 angular contact ball bearings in front and 2 large aperture angular contact ball or roller(optional) bearings in rear side, to fulfil axial and radial cutting carrying requirements at same time. Servo Tailstock: Substantially shorten un-processing time due to servo driven. high rigidity tailstock. Less operation steps. Setup time: reduce 50%. Operation time: reduce 20%. Programe different pressure by codes Sub Spindle: Built-in Motor Spindle : High Precesion: The bigger spindle bearings and the appropriate wide spacing between the guideways ensure that HT series machines by high accuracy and rigidity. Iron Bed: High stability and perfect machining results thanks to the integrally molded massive hT300 cast iron bed.

Overall: The machine tool has a mechanical, electrical, and hydraulic integrated layout. The 45° overall slant bed has the advantages of compact structure, high rigidity, smooth chip removal, and convenient operation. The guide rail type is a rolling guide rail, and the driving parts are high-speed silent ball screws. It has the advantages of fast speed, less heat, and high positioning accuracy; the machine tool is fully enclosed protection, automatic chip removal, automatic lubrication, automatic cooling. Spindle: The main drive unit of this machine tool is driven by Japanese FANUC 11/15kw high-performance servo motor, which drives the spindle to rotate through a pair of pulleys. The spindle speed range is 30-4500r/min. The front support of the main shaft adopts three-set high-precision angular contact ball bearings, and the rear support adopts two high-precision angular contact ball bearings with large apertures to meet the bearing requirements of axial and radial cutting forces. Tailstock:The Hydraulic Cylinder is used to drive the integral mobile tailstock. The structure is simple, with high precision, high rigidity and reliable performance. Turret: The machine used servo hydraulic turret, with fast tool change speed and high reliability. Drive:The X-axis and Z-axis driving adopts FANUC high-performance servo motor, with high positioning accuracy and flexible and reliable action. System: The control system is FANUC 0iTF+, using high-performance AC spindle motor and servo motor.

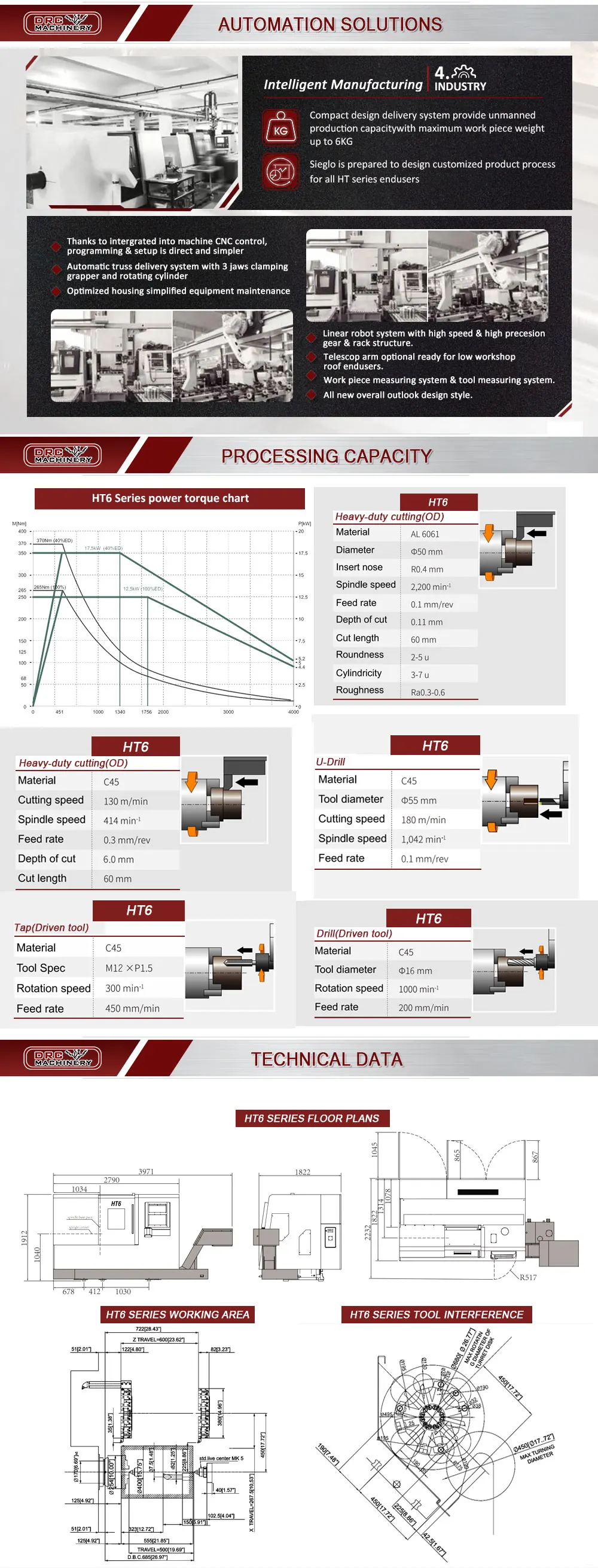

CNC Turning lathe Center Features: Thanks to intergrated into machine CNC control, programming setup is direct and simpler. Automatic truss delivery system with 3 jaws clamping grapper and rotating cylinder. Optimized housing simplified equip ment maintenance. Linear robot system with high speed high precesion gear rack struc-ture. Telescop arm optional ready for low workshop roof endusers. Work piece measuring system tool measuring system. All new overall outlook design style.

Automatic truss delivery system optional for all HT series machine models Developed automatic truss delivery system based on HT series, is specially designed for HT models. DRC Machinery provides one-stop service of complete intergrated system including turning center and automation system. Therfore machines and automatic system only need one control system to manage all jobs. This helps maintain and operate the whole system more easier. Up to 6 KGs work piece loading capacity, faster, simpler to operator and more flexible. Maximum availbale work piece size is p200*150mm.

Energy saving Functions &Technoligies:

Spindle Chiller System. Automatic power-off all accessories after automation producing cycles.

Automatic power saving mode under no load rotating Lightweight design &low inertia design ideas.

High performance single cpu structure. Simplified machanic structure design for energy saving.

Displayer auto power saving mode. Complete thermal equilibrium design ideas.

Size Information

Technical date | ||||

Spindle head | Type | FL 170 h5 | ||

Spindle maximum speed | rpm | 4000 | ||

Max. Torque | N×m | 256 | ||

Spindle power | Kw | 15-18.5 | ||

Chuck diameter | mm | 250 | ||

Spindle bore | mm | 87 | ||

Front bearing diameter | mm | 130 | ||

Spindle bearing lubrication | Type | Grease | ||

Linear motion lubrication | Type | Oil | ||

Speed range | rpm | 5-4000 | ||

Work area | ||||

Maximum swing over bed | mm | 670 | ||

Maximum cutting diameter | mm | 400 | ||

Maximum cutting length | mm | 550 | ||

Maximum bar capacity | mm | 65 | ||

Travel of Z-axis | mm | 600 | ||

Travel of X-axis | mm | 240 | ||

Travel of Y-aixs | mm | ±55 | ||

Ball screw | ||||

X/Z axis ballscrew DxP | mm | 40 x 10/40 x 5/40 x 10 | ||

Feed | ||||

Rapid traverse Z | m/min | 24 | ||

Rapid traverse X | m/min | 24 | ||

Rapid traverse Y | m/min | 12 | ||

Rapid traverse C | m/min | 100 | ||

Feed force | ||||

Feed force X/Z | N m | 7500 | ||

Number of axis | 4 | |||

Measuring system | ||||

X/Y/Z axis measuring system | Absolute rotative | |||

(X / Y/ Z);VDI/DGQ 3441 Positioning | mm | 0.008/0.008/0.01 | ||

(X / Y/ Z);VDI/DGQ 3441 Repeatability | mm | 0.005/0.005/0.008 | ||

Tool attachments | ||||

Power turret | Type | BMT55 | ||

No. of tool stations Driven tools | # | 12 | ||

T-T time | sec | 0.25/0.5 | ||

OD tool size | mm | 25/40 | ||

Maximum speed of tool driven | rpm | 3000 | ||

Tool driven power | Kw | 3 | ||

Max. torque of tool driven | N×m | 45 | ||

Electrical specifications | ||||

Voltage | V | 380 ±10% | ||

Frequency | Hz | 50 ± 1% | ||

Max. installed power | KVA | 35 | ||

400v lie protection fuses | A | 100 | ||

Connection cables section | mm2 | 4 x 10 | ||

Hydraulic unit | ||||

Max. working pressure | bar | 50 | ||

Reservoir capacity | l | 40 | ||

Pump flow | I/ in | 24 | ||

Coolant system | ||||

Capacity with tank | l | 180 | ||

Pump delivery | l /min | 30 | ||

Pump pressure | bar | 5 | ||

Noise level | ||||

Less than | dB (A) | ≤80 | ||

Control system | ||||

FANUC | - | 0iTF plus+MGi(Manual guide i) | ||

Net weight | kg | About 5500 | ||

Slant angle, Material | - | 45°, castiron | ||

Related Products

FAQ

1. What is your minimum order quantity and warranty?

MOQ is one set, and warranty is one year.

2.What CNC system do you use?

FANUC, SIEMENS, MISTSUBISHI, GSK etc. It depends on your choice.

3.When is the delivery time?

We will delivery it within 90 days after received your payments

4. How to handle the warranty period?

During the warranty period, because of product quality problems, the company is responsible for free maintenance, if need to change parts, we be responsible for free replacement.

If the machine problem is not belonging to our machine quality problems, when the buyer needs us send engineers to give repairing service, we charge the appropriate cost.

5.Can your company send the technical personnel to our company and direct our workers for free?

When the machine arrive the buyer’s installation site, we timely send mechanical and electrical engineers to install according to the buyer's schedule, the buyer undertakes board and lodging of personnel abroad in the process of installation, and also USD100.00 per day per person. The seller will cooperate with the buyer to deal with visa and installation preparation before going abroad.

6.What's the trade assurance?

When you look at our alibaba website, you will see the trade security, its purpose is to let every buyer confidence, it can

protect your payment, ensure that the suppliers fulfill their commitment to the date of shipment and the quality of the products(as you stated in the purchase order).

If the supplier finds breach of these contractual obligations, alibaba will indemnify you for 100% of your trade guarantee.

Therefore, I believe that through trade guarantees, you will have greater confidence to cooperate with us.

Our company has US $128000' trade assurance limit, it can guarantee your interests.

7.Do your products support trade assurance?

Yes, our products are all supported.

MOQ is one set, and warranty is one year.

2.What CNC system do you use?

FANUC, SIEMENS, MISTSUBISHI, GSK etc. It depends on your choice.

3.When is the delivery time?

We will delivery it within 90 days after received your payments

4. How to handle the warranty period?

During the warranty period, because of product quality problems, the company is responsible for free maintenance, if need to change parts, we be responsible for free replacement.

If the machine problem is not belonging to our machine quality problems, when the buyer needs us send engineers to give repairing service, we charge the appropriate cost.

5.Can your company send the technical personnel to our company and direct our workers for free?

When the machine arrive the buyer’s installation site, we timely send mechanical and electrical engineers to install according to the buyer's schedule, the buyer undertakes board and lodging of personnel abroad in the process of installation, and also USD100.00 per day per person. The seller will cooperate with the buyer to deal with visa and installation preparation before going abroad.

6.What's the trade assurance?

When you look at our alibaba website, you will see the trade security, its purpose is to let every buyer confidence, it can

protect your payment, ensure that the suppliers fulfill their commitment to the date of shipment and the quality of the products(as you stated in the purchase order).

If the supplier finds breach of these contractual obligations, alibaba will indemnify you for 100% of your trade guarantee.

Therefore, I believe that through trade guarantees, you will have greater confidence to cooperate with us.

Our company has US $128000' trade assurance limit, it can guarantee your interests.

7.Do your products support trade assurance?

Yes, our products are all supported.

Product Categories : CNC Lathe > Slant Bed CNC Lathe

Premium Related Products

Other Products

Hot Products

Multifunctional CNC LatheChina Mini Lathe Machine Czk0640A CNC Lathe Drill Mill Tap CNC Machine PriceChina Mini Lathe Machine Czk0640A CNC Lathe Drill Mill Tap CNC MachineMini CNC Lathe Machine Ck6125 Small Size Lathe MachineCNC Pipe Thread Lathe Ckg1322A CNC Lathe MachineCNC Lathe Machine Ck6180W CNC Wheel Repair Lathe with Good Price From Taian HaishuHigh precision CNC planer Type boring miller mill planer borer machine price for saleHigh precision cnc vertical milling lathe machine for saleHigh precision used fanuc cnc milling machine for saleHigh precision cnc lathe lathes machine price for saleHigh precision Roll-turning lathe machine price for saleSingle Column NC Vertical Lathe with Elevating Railheavy duty large Horizontal Lathes machine price for saleHigh speed used haas cnc lathe diy metal latheHigh speed metal working lathe machine price for saleBridge Type CNC Milling Machine For Sale