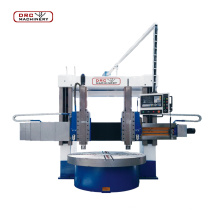

3 Axis Vertical CNC Turning Machining Vs Milling Center VMC 1160 Machine Centre Price

Product Description

3 Axis Vertical CNC Turning Machining Vs Milling Center VMC 1160 Machine Centre Price

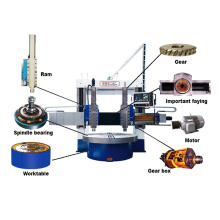

The Vertical Machining Center is suitable for high-efficiency and high-precision automatic processing of small and medium-sized metal and non metal hardparts in aerospace, military and national defense automobile and motorcycle, engineering machinery refrigeration, and petrochemical, rolling stock and other industries.

The system and all the configuration we can customized according to customers request.

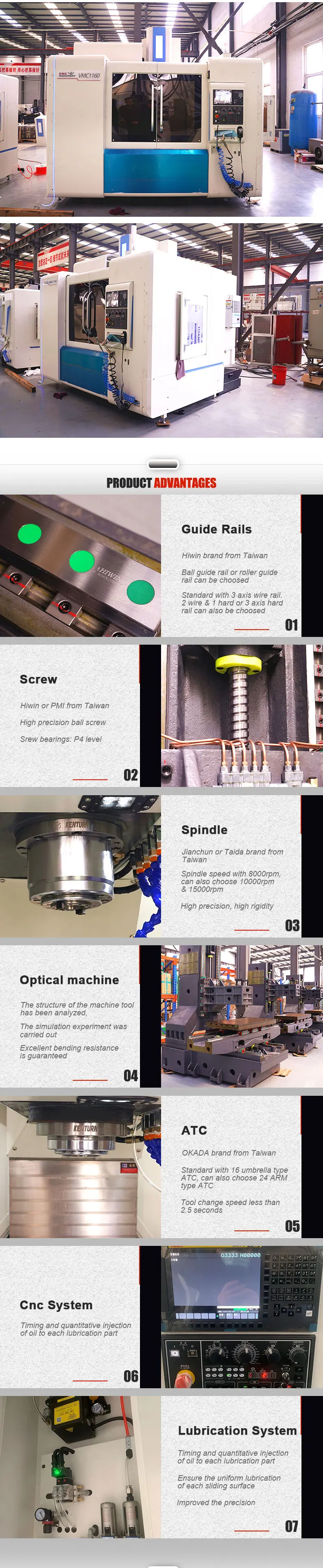

The CNC Milling Machine tool adopts high-speed, high-precision and high-rigidity spindle unit. Spindle material is made of high-performance alloy steel. The high-speed precision bearing for the spindle is used, and high-speed grease is used. The spindle speed reaches 8000rm.

X,Y, Z direction feed adopts C3 grade double nut preloaded precision ball screw.

Retractable MPG for easy operation.

Customizable tool magazine.

The servo motor is directly connected with the Iead screw through highto torque and Iow Inertia imported elastic coupling to ensure positioning accuracy and repeat positioning accuracy .

High rigidity. The main basic parts are analyzed by finite element structure , the structure is reasonable and the rigidity is Iarge . all Machine Tool castings are hot. Aging treatment , precision has long-term stability .

| VMC 1160 (GSK system) | |

| Travel parameters of 3 axis |

|

| X /Y/Zaxis travel | 1100/600/620mm |

| Spindle face to table distance | 120-720mm |

| Distance between spindle center and column guide surface | 675mm |

| Worktable parameters |

|

| Worktable size | 1200×600mm |

| Maximum load bearing of worktable | 1000kg |

| T Shot | 5×18×120mm |

| Feeding parameters |

|

| X/Y/Z axis rapid movement rate | 24/24/24m/min |

| Feed moving velocity X, Y, Z | 1-10m/min |

| Spindle parameters |

|

| Main shaft connection | Belt |

| Spindle taper | BT40-150 |

| Range of spindle speed | 8000rpm(Optional:10000 ) |

| Spindle motor power | (Alternating current servo)11kW |

| ATC paremeters |

|

| ATC capacity | 24qty |

| Maximum tool size | Φ350/250mm/Φ150mm(tool from a distance) |

| Maximum tool weight | 8kg |

| Precision |

|

| PositionaI accuracy(JIS standard) | ±0.008/300mm |

| Repeated positioning accuracy(JIS standard) | ±0.005mm |

| Shape and weight |

|

| Machine size | 3100×2550×2900mm |

| Weight | 6800kg |

| Standard accessories |

|

| GSK 998 CNC System | Bt40-150-8000rpm belt spindle |

| Machine tool lighting working lamp | Centralized automatic feed lubrication system |

| Spindles clean the air | Spindle taper: BT40 |

| Chip liquid system | Tricolor warning light |

| 10.4 "display | Separate handwheel |

| Servo transformer | RS232 interface |

| Foundation gasket and adjusting bolt | Three ball type linear guide rail |

| Random technical document | Three-axis precision grinding ball screw |

| Electrical cabinet cold and heat exchanger |

|

Product Categories : Other Lathe Machine > Machine Centre

Premium Related Products