CNC lathe and milling machine combo IHT316 Siemens Hydraulic horizontal mini metal cnc lathe machine turning center

Product Description

CNC Lathe and Milling Machine combo IHT316 Siemens Hydraulic horizontal mini metal CNC lathe machine turning center

What Is The Specifications of IHT series CNC Lathe ?

| Parameter | |

| Spindle head | FL 140 h5 |

| Spindle maximum speed | 4500 rpm |

| Max. Torque | 112 N×m |

| FANUC Spindle power | 7.5-11 kW |

| Chuck diameter | 165 mm |

| Spindle bore | 74 mm |

| Front bearing diameter | 100 mm |

| Spindle bearing lubrication | Grease |

| Linear motion lubrication | Oil |

| Speed range | 5-4500 rpm |

| Work area | |

| Center distance | 608 mm |

| Maximum swing over bed | 558 mm |

| Maximum cutting diameter | 340 mm |

| Maximum cutting length | 355 mm |

| Maximum bar capacity | 42 mm |

| Travel Z/X | 380 /180 mm |

| Ball screw | |

| X/Z axis ballscrew DxP | 32 x 10 mm |

| Feed | |

| Rapid traverse Z/X | 30/30 m/min |

| Feed force of axis | |

| Feed force X/Z | 4500 N m |

| Number of axies | 2 |

| Measuring system | |

| X/Z axis measuring system | Absolute rotative |

| (X / Z);VDI/DGQ 3441 Positioning | 0.008/0.008 mm |

| (X/ Z);VDI/DGQ 3441 Repeatability | 0.004/0.005 mm |

| Tool attachments | |

| Servo turret | INVESTA |

| No.of tool stations | 8 |

| Turret disk type | Slot disk |

| Tool attachment | 25 mm |

| Electrical specifications | |

| Voltage | 380 ±10% V |

| Frequency | 50 ± 1% Hz |

| Max. installed power | 20 KVA |

| 400v lie protection fuses | 50 A |

| 400v line automatic circuit breaker | 33 A |

| Connection cables section | 4 x 10 mm2 |

| Hydraulic unit | |

| Max. working pressure | 55 bar |

| Reservoir capacity | 35 l |

| Pump flow | 24 I/ min |

| Oil-based coln system | |

| Capacity with tank | 100 l |

| Pump delivery | 30 l /min |

| Pump pressure | 5 bar |

| Noise level | |

| Less than | ≤80 dB (A) |

| Siemens Control system | Siemens 808AD |

| Net weight | About 3200 kg |

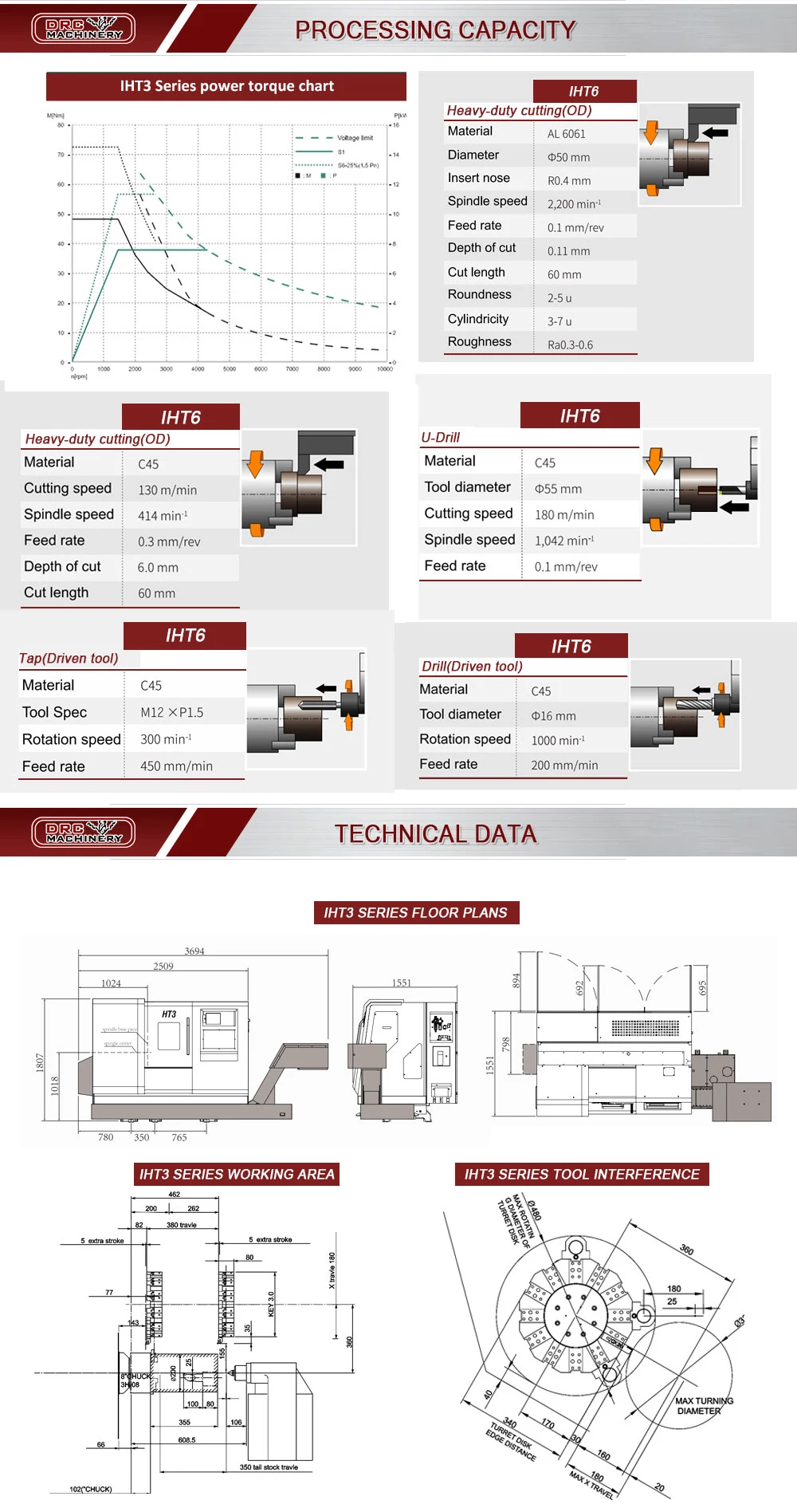

Overall: The machine tool has a mechanical, electrical, and hydraulic integrated layout. The 45° overall slant bed has the advantages of compact structure, high rigidity, smooth chip removal, and convenient operation. The guide rail type is a rolling guide rail, and the driving parts are high-speed silent ball screws. It has the advantages of fast speed, less heat, and high positioning accuracy; the machine tool is fully enclosed protection, automatic chip removal, automatic lubrication, automatic cooling.

Spindle: The main drive unit of this machine tool is driven by Japanese FANUC 11/15kw high-performance servo motor, which drives the spindle to rotate through a pair of pulleys. The spindle speed range is 30-4500r/min. The front support of the main shaft adopts three-set high-precision angular contact ball bearings, and the rear support adopts two high-precision angular contact ball bearings with large apertures to meet the bearing requirements of axial and radial cutting forces.

Tailstock:The Hydraulic Cylinder is used to drive the integral mobile tailstock. The structure is simple, with high precision, high rigidity and reliable performance.

Turret: The machine used servo hydraulic turret, with fast tool change speed and high reliability.

Drive:The X-axis and Z-axis driving adopts FANUC high-performance servo motor, with high positioning accuracy and flexible and reliable action.

System: The control system is FANUC 0iTF+, using high-performance AC spindle motor and servo motor.

1. What is your minimum order quantity and warranty?

MOQ is one set, and warranty is one year.

2.What CNC system do you use?

FANUC, SIEMENS, MISTSUBISHI, GSK etc. It depends on your choice.

3.When is the delivery time?

We will delivery it within 90 days after received your payments

4. How to handle the warranty period?

During the warranty period, because of product quality problems, the company is responsible for free maintenance, if need to change parts, we be responsible for free replacement.

If the machine problem is not belonging to our machine quality problems, when the buyer needs us send engineers to give repairing service, we charge the appropriate cost.

5.Can your company send the technical personnel to our company and direct our workers for free?

When the machine arrive the buyer’s installation site, we timely send mechanical and electrical engineers to install according to the buyer's schedule, the buyer undertakes board and lodging of personnel abroad in the process of installation, and also USD100.00 per day per person. The seller will cooperate with the buyer to deal with visa and installation preparation before going abroad.

6.What's the trade assurance?

When you look at our alibaba website, you will see the trade security, its purpose is to let every buyer confidence, it can protect your payment, ensure that the suppliers fulfill their commitment to the date of shipment and the quality of the products (as you stated in the purchase order).

If the supplier finds breach of these contractual obligations, alibaba will indemnify you for 100% of your trade guarantee.

Therefore, I believe that through trade guarantees, you will have greater confidence to cooperate with us.

Our company has US $128000' trade assurance limit, it can guarantee your interests.

7.Do your products support trade assurance?

Yes, our products are all supported.

Send your Inquiry Details in the Below , Click "Send" Now !