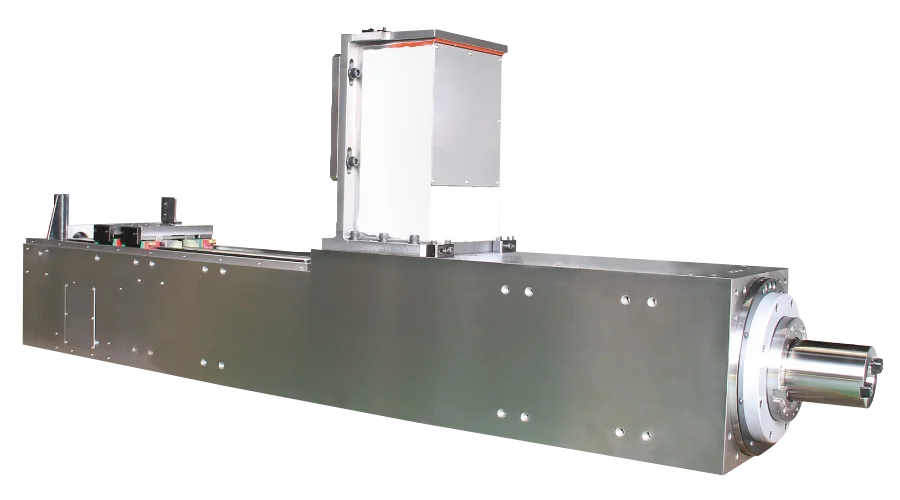

Horizontal boring and milling machining centers

Product Description

Horizontal boring and milling machining centers

Main Features

1.Spindle adopts German A.M Technology (22/30kw), the maximum speed of up to 3000rpm.

2.The shaft is replaced by the ZF gear box to replace the traditional gear, increasing the spindle torque, and ensuring the stability of the boring depth accuracy

3.The spindle broach is up to 2500-2700kgf, increased by 20% than the other manufacturers.

4.Worktable with the surface by steel combination, cancel the wear plate, using hydraulic technology, so as to strengthen the work of Taiwan wear resistance, to ensure the stability and the service life of precision worktable

5.The X and Z axis adopt heavy duty linear roller guide rail. They are of good rigidity, high accuracy and long service life

Main Parameter

Model | Unit | DBM110A | DBM130 | DBM130B | ||||

X-axis travel | mm | 2000/2500 | 2500 | 4500 | ||||

Y-axis travel | mm | 1800 | 2200 | 3500 | ||||

Z-axis travel | mm | 1500 | 1500 | 2000 | ||||

W-axis travel | mm | 550 | 700 | 700 | ||||

Spindle | ||||||||

Center of spindle worktable surface | mm | 80~1880 | 125~2125 | 125~3625 | ||||

Nose of spindle to work center | mm | -50~2000 | -40~2160 | 200~2900 | ||||

Spinde diameter | mm | 110 | 130 | 130 | ||||

Spindle taper | ISO 50 | ISO 50 | ISO 50 | |||||

Rotating spindle speed (standard) | rpm/min | 35~3500 | 35~3000 | 35~3000 | ||||

Number of steps of rotating speed of spindle | 2 Steps | 2 Steps | 2 Steps | |||||

Transmission mode | Gear box | Gear box | Gear box | |||||

Worktable | ||||||||

Table size (optional) | mm | 1250×1500 | 1400×1600 (1600×1800) | 2500×2500 | ||||

Division angle | deg | 0.001° | 0.001° | 0.001° | ||||

Reference aperture | mm | 140H7 | Φ140H7 | Φ140H7 | ||||

Max. load on worktable | kg | 5000 | 8000/10000/12000 | 20000/25000 | ||||

T-shot | mm | 22H7×160×7 | 24H7×200×7 | 28H7×150×15 | ||||

Division precision | sec | 15 | 15 | 15 | ||||

Repetitive locating precision | sec | 4 | 4 | 4 | ||||

Tool magazine and automatic toolchanger (optional) | ||||||||

Capacity of tool magazine | 40 | 60 | 60 | |||||

Tool selecting mode | Absolute | Absolute | Absolute | |||||

Tool changing type | Arm type | Arm type | Arm type | |||||

Tooling | BT/CAT/DIN #50 | BT/CAT/DIN #50 | BT/CAT/DIN #50 | |||||

Max. tool weight | kg | 25 | 25 | 25 | ||||

Max. tool length | mm | 500 | 500 | 500 | ||||

Max. tool diameter (no adjacent tool) | mm | Φ125/250 | Φ125/250 | Φ125/250 | ||||

Spindle and motor | ||||||||

Spindle motor | kw | FANUC 18.5/22 | FANUC 22/30 | FANUC 22/30 | ||||

Max. torque of spindle | Nm | 965/1155 | 3011/4109 | 3011/4109 | ||||

Locating precision of Machine Tool | mm | ±0.010 | ±0.010 | ±0.010 | ||||

Repetitive locating precision of machine tool | mm | ±0.005 | ±0.005 | ±0.005 | ||||

Others | ||||||||

Floor area (length×width×height) | mm | 6405×6250×5415 | 7690×6790×5000 | 7690×9690×6500 | ||||

Machine weight | kg | 30900 | 40000 | 55000 | ||||

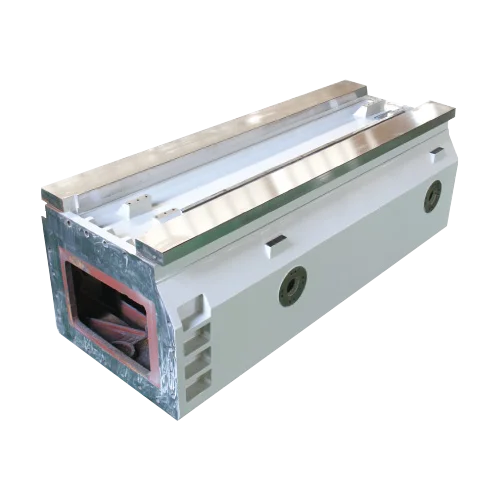

X/Y/Z Axis structures

Spindle

Gear type main shaft head are integrally cast molding, has a higher rigidity than the average combined type main shaft structure, improves the stability of the machine.

Spindle using large spacing, cylindrical rollers NN bearing ultra precision, ultra rigid, therefore has excellent processing capability for heavy cutting.

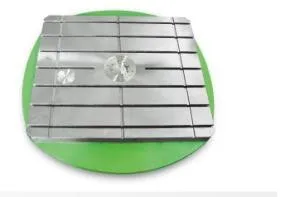

Worktable

Indexing action is kept reliable and stable dependent on drive of large-diameter sliding surface and double gears 90°locating pins independently researched .

In addition hydraulic and T-bolts are used for solid clamp. Furthermore, backboard is used to prevent float of worktable under strong clamp of hydraulic and T-bots.

1. What is your minimum order quantity and warranty?

MOQ is one set, and warranty is one year.

2.What CNC system do you use?

FANUC, SIEMENS, MISTSUBISHI, GSK etc. It depends on your choice.

3.When is the delivery time?

We will delivery it within 90 days after received your payments

4. How to handle the warranty period?

5.Can your company send the technical personnel to our company and direct our workers for free?

When the machine arrive the buyer's installation site, we timely send mechanical and electrical engineers to install according to the buyer's schedule, the buyer undertakes board and lodging of personnel abroad in the process of installation, and also USD100.00 per day per person. The seller will cooperate with the buyer to deal with visa and installation preparation before going abroad.

Product Categories : Boring&Milling Machine